Roads fulfil a crucial function in modern society, providing increased mobility for people, goods and services. They have played a key role in European progress and continue to drive socio-economic growth.

Asphalt road surfaces offer many benefits, including cost efficiency, reduction in noise pollution and comfort. Using asphalt materials in road construction and maintenance can improve the benefits for all road users and the environment.

The advantages of asphalt simply add up to superior value. Asphalt is safe, smooth and durable. It can be built constructed to last indefinitely. Asphalt is fast to construct and maintain and asphalt contractors know how to “get in and get out” of construction zones. Asphalt is the green pavement: It is up to 100% reusable resp. recyclable. Furthermore, its flexibility and new technologies are making asphalt the only sustainable pavement choice.

For more information have a look at the EAPA Documents:

Sustainability:

- EAPA Position Statement on the Use of Secondary Materials, By-products, and Waste in Asphalt Mixtures (2017)

- EAPA Guidance Document for Preparing PCRs and EPDs for Asphalt Mixtures (2017)

- The use of Warm Mix Asphalt (2014)

- Asphalt the 100% recyclable construction product (2014)

- Arguments to simulate asphalt reuse and recycling (2008)

- Abatement of traffic noise… … the arguments for asphalt (2007)

- Recycling of Asphalt Mixes and Use of Waste in Asphalt (2005)

Performance:

The advantages of asphalt simply add up to superior value. Asphalt is safe, smooth, durable and sustainable.

Asphalt is Smooth & Comfortable

Asphalt will consistently give the driving public the smooth, quiet ride they have come to expect from this product. Asphalt is a flexible pavement built in multiple layers with a continuous flow of material moving through the asphalt paver. Repetitive construction joints, noisy surface texture, and blow ups are eliminated by this method of construction. This construction method creates the smooth and quiet ride with low rolling resistance, which makes possible up to 5% reductions in fuel consumption and CO2 emissions for passing vehicles.

These features benefit airport users too. Asphalt runways and taxiways mean safer landings and take offs, because such surfaces are smoother and easier to maintain.

Asphalt is Cost-efficient

Asphalt has low initial costs, lasts long, and due to its recyclability, has residual value greater than other pavements. (from: https://www.apai.net/Files/content/Asphalt/Asphalt_Benefits_Page.pdf)

Reclaimed asphalt contains a lot of bitumen, and reheating and reusing it is simple. Therefore reclaimed asphalt is a valuable raw material as bitumen is the most expensive component of asphalt. For these reasons reusing reclaimed asphalt produces considerable savings, especially if the transportation distances of the reclaimed old asphalt are reasonably short.

Asphalt containing reclaimed asphalt is just as good as new – The standards and regulations of the asphalt industry favour the use of reclaimed asphalt as a raw material in asphalt production. Same quality requirements are posed on both asphalt made from new materials and asphalt containing reclaimed asphalt, making reused asphalt just as high quality, clean and durable as new asphalt.

Kompact asphalt 2858-1

Reusing asphalt yields notable savings in the costs of materials and logistics. These savings alone, especially due to saving on new bitumen, make reusing asphalt economical. Reusing the aggregate also offers savings, especially in countries that have to import it. Reusing asphalt reduces the need and cost of transportation, significantly reducing emissions at the same time. (from: Sustainable asphalt – Recycling; The Nordic Road Forum, NVF, 5/2012)

It’s not just in actual cost, but also in terms of the time it takes to complete construction. Asphalt is so quick and easy to use that it saves the public, government and contractors time and money.

Another advantage of asphalt is that only the necessary pavement thickness (depending on traffic and the climate) must be applied to get a durable, cost-effective and sustainable road.

Asphalt is Safe

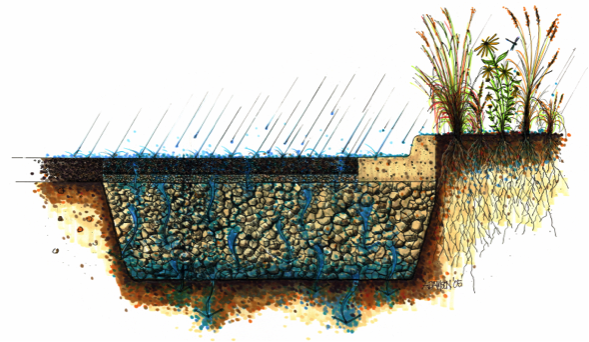

New asphalt technology ensures rapid dispersal and drainage of surface water, reducing water spray and therefore, improving visibility for the driver in wet conditions. The porous asphalt materials dramatically reduce blinding spray, and by dispersing surface water they also reduce the risk of aquaplaning and increase the visibility of road markings.

The variety of asphalt mixtures offers specifiers the right solution for all types of road and weather conditions, maximising safety for all road users. Although we talk about ‘asphalt’, there is a wide range of types and mixtures available, all of which have qualities tailored for specific applications. For example there are asphalt mixtures that allow heavy rain to drain swiftly from the surface. There are also mixtures that can be designed to a texture on the asphalt surface with high skid resistance for areas likely to experience hard braking. (Fit for tomorrow – Asphalt Paving: Safe, Comfortable, Sustainable; EAPA & Eurobitume Brochure 2011)

The smooth surface of asphalt provides maximum tire contact with the roadway, increasing skid resistance. (from: https://www.apai.net/Files/content/Asphalt/Asphalt_Benefits_Page.pdf)

Coloured asphalt is also used to alert driver attention to dangerous areas, such as hidden junctions or sharp bends, as well as areas requiring special safety precautions, such as outside schools.

Fast construction of asphalt roads means shorter time for the workers on the construction site. They “get in and get out”, and this significantly reduces safety risks both for the workers and the road users.

The contrast of the black pavement and white lines make it easier for motorists to understand driving and parking regulations – making asphalt a safer pavement. (from: https://www.alphapavingtexas.com/faq-answer/what-are-the-main-benefits-of-asphalt)

Another recent asphalt advance has been the development of coloured or textured surfaces. These are increasingly used as a safety mechanism to make it easier for drivers to identify lanes set aside for special uses, such as bus lanes, bus stops and cycle paths.

Coloured asphalt is also used to alert driver attention to dangerous areas, such as hidden junctions or sharp bends, as well as areas requiring special safety precautions, such as outside schools.

Asphalt is Durable and can be constructed to Last Indefinitely

Asphalt pavements are often built using thick base courses for bearing the main load above an unbound granular layer. Next, a strong-load bearing intermediate course (binder course) is placed over the base course. The intermediate (binder) course is followed by 30-40 mm surface course. Properly designed, constructed and maintained intermediate and base courses remain strong and viable for many decades and sometimes without ever needing total reconstruction. With asphalt mixes, such as Stone Mastic Asphalt, the wearing course can last more than 30 years. When this wearing course has to be renewed/replaced, it is milled off, and then reused into a new asphalt layer. In addition, latest advances in self-healing asphalts indicate that service life of wearing courses might get extended very significantly in modern roads. More information can be found in: Long-Life Asphalt Pavements, Technical version, EAPA Paper, June 2007.

Fast to construct

Asphalt is Fast to Construct and to Maintain

Asphalt pavements are fast to construct. Because asphalt effectively does not need “cure” time, motorists can use roadways as soon as the last roller leaves the construction zone. This means fewer delays and safer roads for the traveling public. (from:https://www.apai.net/Files/content/Asphalt/Asphalt_Benefits_Page.pdf)

These properties of asphalt roads mean that they can be easily opened and quickly reinstated almost immediately. This is very important for general road maintenance in order to maintain roads for extending the lifetime of the road structure, providing a safe and smooth road surface for vehicles.

The lack of pavement joints reduces maintenance requirements. Because asphalt pavements have no joints to repair and are not affected by freeze- thaw actions, it is much less expensive to maintain. (from:https://www.apai.net/Files/content/DesignGuide/Chapter_1B.pdf )

Asphalt-surfaced roads are easy to upgrade when traffic volumes rise – the existing surface can easily be strengthened by applying an overlay or lane widening rather than having to be reconstructed. This flexibility of application also means that asphalt roads can remain partly open whilst they are being upgraded, and without the need for long curing periods can be re-opened quickly helping to keep traffic running. (from: Fit for tomorrow – Asphalt Paving: Safe, Comfortable, Sustainable; EAPA & Eurobitume Brochure 2011)

Asphalt is up to 100% Reusable

Asphalt is one of the most recycled construction product in Europe. It makes asphalt pavements sustainable. Less new bitumen is needed to make new asphalt pavements and million tons of new aggregate can be saved. It is even possible to create a pavement from almost 100% reclaimed asphalt. (EAPA Position Statement on the Use of Secondary Materials, By-products, and Waste in Asphalt Mixtures (2017))

The reclaimed asphalt is collected and transported to the nearest asphalt plant or other appropriate location. At the plant the asphalt can be crushed and the crushed asphalt granules are used for new asphalt. In many cases milled asphalt can be reused without additional crushing. It is common to resurface worn out asphalt by milling the top layer, so the new asphalt can be laid on an even surface. Many asphalt plants have the appropriate equipment to reuse reclaimed asphalt (RAP).

The asphalt industry is one of the forerunners of recycling and reuse. Asphalt is 100% recyclable, meaning practically that all of the Reclaimed Asphalt is either reused or recycled. In average terms, in Europe 68% of reclaimed asphalt is reused in the manufacture of new mixes (especially HMA and WMA), 19% is recycled as granular material in unbound road layers, 1.25% is used in other applications of civil engineering and the remaining 11% is put to landfill. (EAPA Position Paper Rejuvenators – August 2018)

Reusing old asphalt has increased in popularity since the seventies. Today’s large scale recycling has been made possible with heavy investments into new machinery. Thanks to these new techniques large quantities of old asphalt are reused. In certain cases over 50 % of the raw materials of new asphalt are RA and in some countries, asphalt pavements containing more than 90% are already being constructed. A part of the old reclaimed asphalt will be recycled as either an unbound or half-bound material for base courses. From an economic and environmental point of view it would be beneficial to reuse most of the recycled asphalt as raw material for new asphalt, making the most use of the bitumen contained within the RA. (from: Sustainable asphalt – Recycling; The Nordic Road Forum, NVF, 5/2012,link: NVF_en)

Asphalt is a recyclable material, it can be used over and over, and its life-cycle never ends. Asphalt roads can be dug up and then re-used again. This is what makes asphalt such a popular, modern day material. When we use it we are preserving our natural resources, by reusing the same material over again.

Asphalt is Flexible

Asphalt surfaces can be ‘tailor-made’ – appropriately formulated and designed to support the traffic load and climatic conditions of a specific road. There are special asphalt mix solutions for motorways, urban, suburban and rural roads and its flexibility is particularly useful in coping with the stresses of large traffic loads on bridges. In areas where roads have to cope with frequent freezing and thawing, thanks to the elasticity of bitumen, asphalt surfaces can be designed to tolerate extreme temperature cycles.

Asphalt is the flexible option for any road. Not just the material itself, but the fact that it can be designed to bring optimal solutions for all types and sizes of roads, lanes, cycle paths etc. For lightly-trafficked pavements, for example in the suburbs, the layers can be thinner. Special traffic or safety features in the road surface like speed ramps, roundabouts and narrowing or widening lanes can also be created. The adaptability of asphalt offers solutions to the many changing requirements of both the road user and our society. (from: Fit for tomorrow – Asphalt Paving: Safe, Comfortable, Sustainable; EAPA & Eurobitume Brochure 2011)

Under urban streets and roads is a vast network of technical infrastructure, such as electrical and communication cables, district heating and water pipes, and sewage. Their building and maintenance requires the opening up of the paving. With asphalt the pavement can be quickly reinstalled.

The flexible composition of the asphalt mixtures to specific regions of the country allows asphalt to adapt to its environment and withstand rutting in the summer and the harsh freeze / thaw cycles of a winter.

Asphalt is the Green Pavement

Research clearly shows that recycling asphalt lowers energy costs and CO2 emissions significantly. This combined with low costs makes recycling an environmentally, economically and industrially important goal. Producing reused asphalt is a clean and safe process. The industry has in use machinery that does not harm the environment and the immediate surroundings. Safety in the workplace and emissions are the same when using reused asphalt as in the production of new asphalt. (from: Sustainable asphalt – Recycling; The Nordic Road Forum, NVF, 5/2012 link: https://www.eapa.org/userfiles/2/Publications/NVF_en.pdf)

Technologies allow the producers of asphalt pavement material to lower the temperatures at which the material is mixed and placed on the road. Such drastic reductions have the obvious benefits of cutting fuel consumption and decreasing the production of greenhouse gases.

As a rule of thumb, a temperature reduction of 25°C can lead to fume emission reduction of about 75%. Hence, the use of Warm and Half Warm Asphalt can produce reductions of 20%-40% in CO2, 20%-35% in SO2, up to 50% in volatile organic compounds (VOC), 10%-30% carbon monoxide (CO) and 60%-70% for nitrous oxides (NOx). Tests for asphalt aerosols/fumes and polycyclic aromatic hydrocarbons (PAHs) also indicated significant reductions of 30%-50% compared to Hot Mix Asphalt. The use of Warm Mix Asphalt (2014)

This “warm-mix asphalt” often compacts better; allows paving crews to work at lower temperatures, extending the paving season; and allows more recycled asphalt to be used in the mix. (from: https://www.asphaltroads.org/assets/_control/content/files/Asphalt_White_Paper_doc.pdf)

Porous asphalt pavements are made so that water can actually drain through the pavement. They are of great interest to site planners and public-works departments because they provide cost-effective storm-water management systems that promote infiltration, improve water quality, and many times eliminate the need for a detention basin. Like other asphalt pavements, they are versatile and can be designed for many situations. Because of the open structure of the pavement, porous asphalt offers a “cooler” pavement choice for application in cities. (from: Asphalt_White_Paper_doc.pdf)

The carbon footprint of asphalt roads is lower than that of alternative products. The availability of today’s reduced-temperature asphalt materials like Warm Mix Asphalt, offering lower mixing and laying temperatures, helps to minimise the energy required to produce asphalt and, as a result, reduces carbon dioxide emissions by as much as 35%. When used together with recycled asphalt, the embodied carbon footprint can be further reduced. (from: Fit for tomorrow – Asphalt Paving: Safe, Comfortable, Sustainable; EAPA&Eurobitume Brochure 2011)

Asphalt is inert in the environment and therefore does not release unwanted substances into the earth or underground aquifers. Asphalt is often used to seal the reservoirs our drinking water comes from and also to line landfill sites to prevent harmful waste materials escaping into the environment (from: Fit for tomorrow – Asphalt Paving: Safe, Comfortable, Sustainable; EAPA&Eurobitume Brochure 2011) and EAPA Position Paper.

- EAPA Guidance Document for Preparing PCRs and EPDs for Asphalt Mixtures (2017)

Asphalt is Reducing Noise Reduction

Use of asphalt road surfaces can significantly reduce noise both inside and outside the car, helping to prevent accidents by alleviating a source of stress that contributes to driver fatigue. Standard asphalt roads have the lowest noise levels of all traditional road surfaces and the more recent development of porous and silent asphalts have reduced noise levels even further. “EAPA Position Paper “EAPA Paper – Abatement of traffic noise – 2007”.

2 Layered Porous Asphalt

Investing in noise-reducing asphalt can lessen the need for alternative, more costly methods of noise reduction such as noise barriers. (from: Fit for tomorrow – Asphalt Paving: Safe, Comfortable, Sustainable; EAPA&Eurobitume Brochure 2011)